VISOR FF: A Thermal Sensor with Exceptional Sensitivity

The VISOR FF camera is a new payload created specifically for the AtlasPRO drone, with a high-quality F/1.0 lens and a thermal sensor with exceptional sensitivity.

“I don’t think we would have started this project if we knew how much effort it would take”, – jokes the Chief Technology Officer.

He is proud of this ATLAS product at the same time. The project of creating this payload was started in 2019. It is planned to finish the working VISOR FF version in 2020. But it happened one year later, in 2021.

VISOR FF is one of the most difficult but very modern and useful products of ATLAS. First of all, this payload was developed with no ITAR technology. VISOR FF is made in the EU.

ITAR is US regulation on dual-use technology (technology which can be used for military systems). It usually is limited to non-US customers (for example, if we use a US-made sensor, we have to get approval from the US government for every customer we sell our products to).

Ivan Tolchinsky, ATLAS CEO and aerospace engineer, says, VISOR FF competes with the same products manufactured in the US in terms of its form, features, and pricing:

“We designed this thermal camera for our own purposes, meaning we wanted to equip our drones with cameras free from ITAR compliance. This helps to shorten the production cycle, simultaneously making the product more affordable for end-users in terms of delivery and pricing. For example, delivery terms are up to six months less than before”.

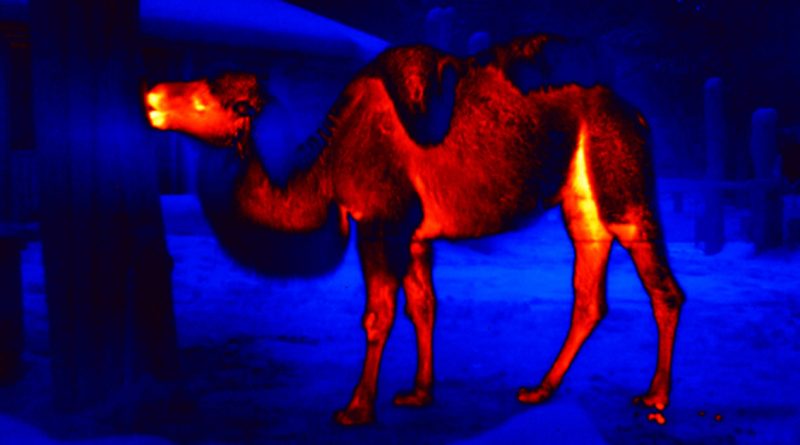

The payload has a unique LWIR sensor with 60 mK sensitivity and a 640×480 | 30fps resolution for accurate temperature measurements. There were quite a few unexpected results during testing. The Chief Technology Officer says:

“I was looking at a weird pattern interposed on the resulting image. After carefully isolating just the pattern, I realized that it was the face of a colleague who was sitting across the room being reflected on the calibration target during the calibration of the camera”.

Some employees gave a nickname for this payload: “The Eye of Sauron”. The camera was seeing its own reflection during calibration – the defect resulted in a hot circle in the middle of the image. Of course, all defects have been corrected successfully during the testing. A calibration of a single camera takes about 20-24 hours, and it is an interesting challenge to schedule production – at some point; inevitably someone has to come to the office at night or on weekends.

In the end, the user has got an innovative device with built-in noise reduction technology, 30 FPS, and thermal 10x digital zoom. VISOR FF takes an image in a few color palettes: White-hot, Back-hot, Rainbow, and Others. The video recording is in TFLC (proprietary format, supported by Atlas Thermal Player), and includes metadata:

• Image sensor GPS coordinates and direction

• Image sensor altitude and angle

• Date and time

• Others

The operation environment of the payload is from -40°C to +55°C, and the storage environment is from -40°C to +65°C.

Features a compact and lightweight design. Its size is 93 x 73 x 99 mm, weight (incl. gimbal) – 271 g.

The VISOR FF is a product that is easy to set up, and which can be installed and launched in less than 30 seconds. It’s available with a gimbal or as a standalone camera.

The ATLAS engineers are now working on the improvements to VISOR FF. In particular, temperature measurement is one recent feature that is being tested currently. And another payload version is getting tested with a higher-focal length lens. Higher magnification can detect and identify targets from further away.

Learn more: https://www.atlasuas.com/